功能特點(dian)

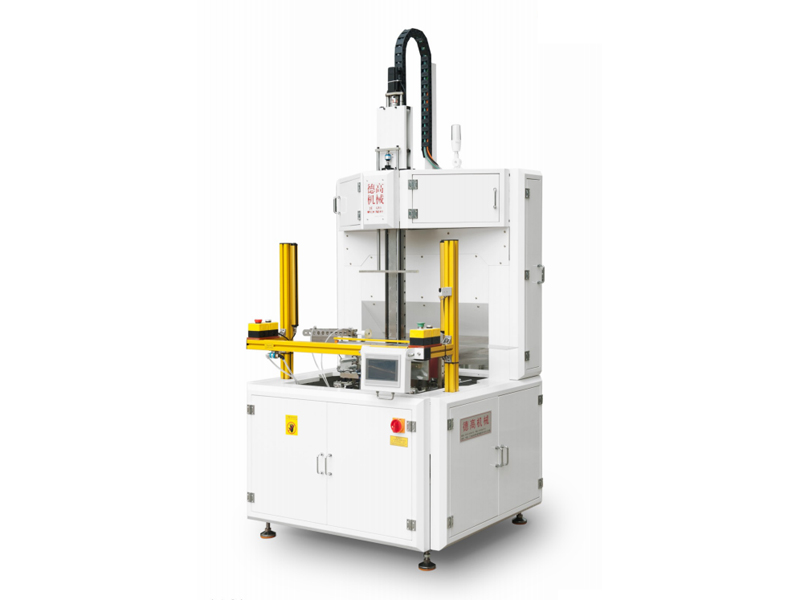

該機融(rong)紙盒的包邊、折入,壓泡為一體,運用伺服驅動斜齒輪(lun)和凸輪完成連貫動作,穩定流暢,精密耐用,是目前相對合理的一款成(cheng)型機,也是廣大禮品盒生産廠家的明智必選機型。

十大功能特點

1.主軸、分模、刷輥、折(zhe)邊、壓泡全部由伺服驅動, 運轉穩定安靜。(.)流暢快(kuai)捷。

2.特有的凸輪、氣缸(gang)兩次盒(he)體除泡功能,可根據情況選擇一次或兩次壓泡。儲氣可(ke)調式底模升降設計,對紙盒底部(bu)除泡力度(du)可調可控。

3.斜齒(chi)機構傳動主軸動作,穩定(ding)、精确、牢國、産量高使(shi)用壽命長,整機(ji)可實現播放式慢動作(zuo)運行,而凸輪機構更可以獲(huo)得平穩的運動.當速度改變時也可以保持同步,調試時更容易觀察(cha)到生産過(guo)程。

4.折耳動作可(ke)做對搭80mm,導軌加氣缸,精密度高,行程(cheng)可定制,能适(shi)應不同産品的生産需求。

5.真空吸盒壓力可調,大小可選不同壓力,有助于人工套盒時的(de)順暢與速度,

6.快速換模調(diao)機設計,程(cheng)序記憶功能,十五分鐘(zhong)完成(cheng)轉版(ban)。(.)

7.進口光栅保護,故障報警(jing),故障區顯示,保障運行操作的安全。

8.加厚台闆,加厚機架,CNC加工中心次完成(cheng).确保運行穩定性和裝配标準化。

9.免換折邊鏟刀和壓泡闆(ban),從小到大的(de)紙盒都可(ke)使(shi)用,

10.調節方式可手動也可以升級為自(zi)動,鎖固方式(shi)可選配。

Functional features

This machine integrates wrapping, folding and pressing of carton into one, and uses servo driven helical gear and cam to complete continuous action. It is stable, smooth, precise and durable. It is a relatively reasonable molding machine at present, and also a wise and necessary model for the majority of gift box manufacturers.

Features

1. The spindle, parting die, brush roller, flanging and bubble pressing are all driven by servo, so the operation is stable and quiet. Smooth and fast.

2. The unique function of twice bubble removing for cam and cylinder can be selected once or twice according to the situation. The air storage adjustable bottom mold lifting design can adjust and control the defoaming force at the bottom of the carton.

3. The helical gear mechanism drives the spindle action, which is stable, accurate, reliable, high output, long service life. The whole machine can realize the slow motion operation of play type, and the cam mechanism can obtain more stable movement. When the speed changes, it can also keep synchronous, and it is easier to observe the production process during debugging.

4. The action of ear folding can be set to 80mm. The guide rail and cylinder have high precision. The stroke can be customized to meet the production needs of different products.

5. The pressure of vacuum suction box can be adjusted, and different pressures can be selected, which is conducive to the smoothness and speed of manual box setting,

6. Quick mold changing and adjusting machine design, program memory function, 15 minutes to complete version transfer.

7. Imported grating protection, fault alarm, fault area display, ensure the safety of operation.

8. Thickened platen, thickened frame and CNC machining center are completed one time to ensure operation stability and assembly standardization.

9. No need to change the folding blade and pressure foam board, which can be used from small to large cartons,

10. The adjustment mode can be manual or upgraded to automatic, and the locking mode can be selected.

微信公衆号

微信公衆号 微信小程序(xu)

微信小程序(xu)

微信公衆号

微信公衆号 微信小程序(xu)

微信小程序(xu)

手機網站

手機網站